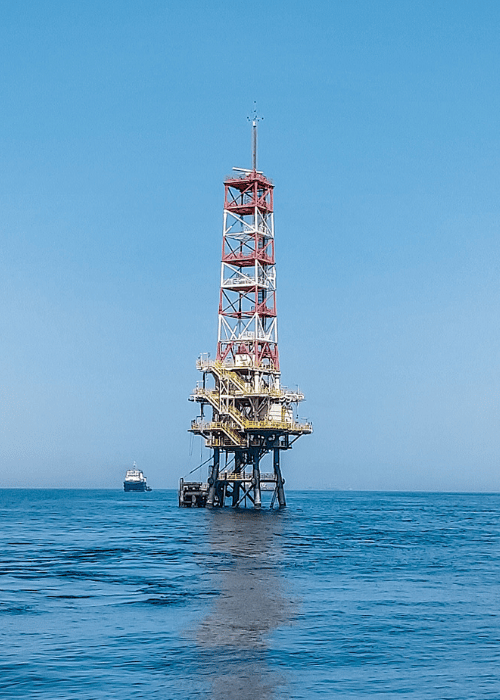

Our oilfield upstream chemicals are designed to optimize the efficiency and reliability of exploration and production processes, addressing key challenges such as corrosion, emulsion stability, and scale formation. Our comprehensive product range includes corrosion inhibitors, demulsifiers, scale inhibitors, and surfactants, all formulated to perform in harsh environments. These chemicals ensure asset integrity, enhance fluid flow, and help maximize production while minimizing operational risks. Additionally, our products are developed with a strong emphasis on sustainability and safety, adhering to stringent regulatory standards and reducing environmental impact. Through rigorous testing and continuous innovation, we provide solutions that support efficient oilfield operations, contributing to a more sustainable industry.

Pour Point Depressants & Paraffin Inhibitors

Demulsifier Intermediates for Petroleum Production and Refining

Corrosion Inhibitors

These inhibitors are also useful as emulsifiers in lubricants for metal working fluids. Additionally, mineral acids can dissolve DAILUBE DE 11 OH in water at about 5%.

Corrosion Co-Inhibitors

H₂S Scavengers

Asphaltene Inhibitors

Our downstream oilfield chemicals are designed to optimize the refining and processing of hydrocarbons, ensuring efficiency and reliability throughout the production process. These specialty chemicals aid in various refining stages, such as improving distillation efficiency, preventing corrosion, and enhancing fuel quality. Our tailored formulations help mitigate challenges like fouling, scaling, and the formation of unwanted deposits, ensuring smoother operations and extended equipment life. By focusing on both performance and environmental compliance, our downstream chemicals support the industry’s drive for cleaner, more efficient production, ultimately helping to deliver high-quality fuels and products to the market.

Pour Point Depressants

For mineral base oils, these products are particularly suitable for lubricants, engine oils, and gear oils. Depending on the application, they can provide significant temperature depression, such as around 21°C in SN 150 and SN 500 base oils, with recommended dosages ranging from 0.05% to 0.4% w/w.

When used in diesel and high-speed diesel (HSD), these pour point depressants and flow improvers are highly effective. The recommended dosages for diesel applications range from 100 to 1000 ppm, depending on the type and source of the diesel. These additives ensure optimal performance in maintaining fluidity and preventing operational issues caused by wax formation.

FCC Metal Passivators

Diesel Fuel Lubricity Improvers

Lubricant Oil Viscosity Index Improvers